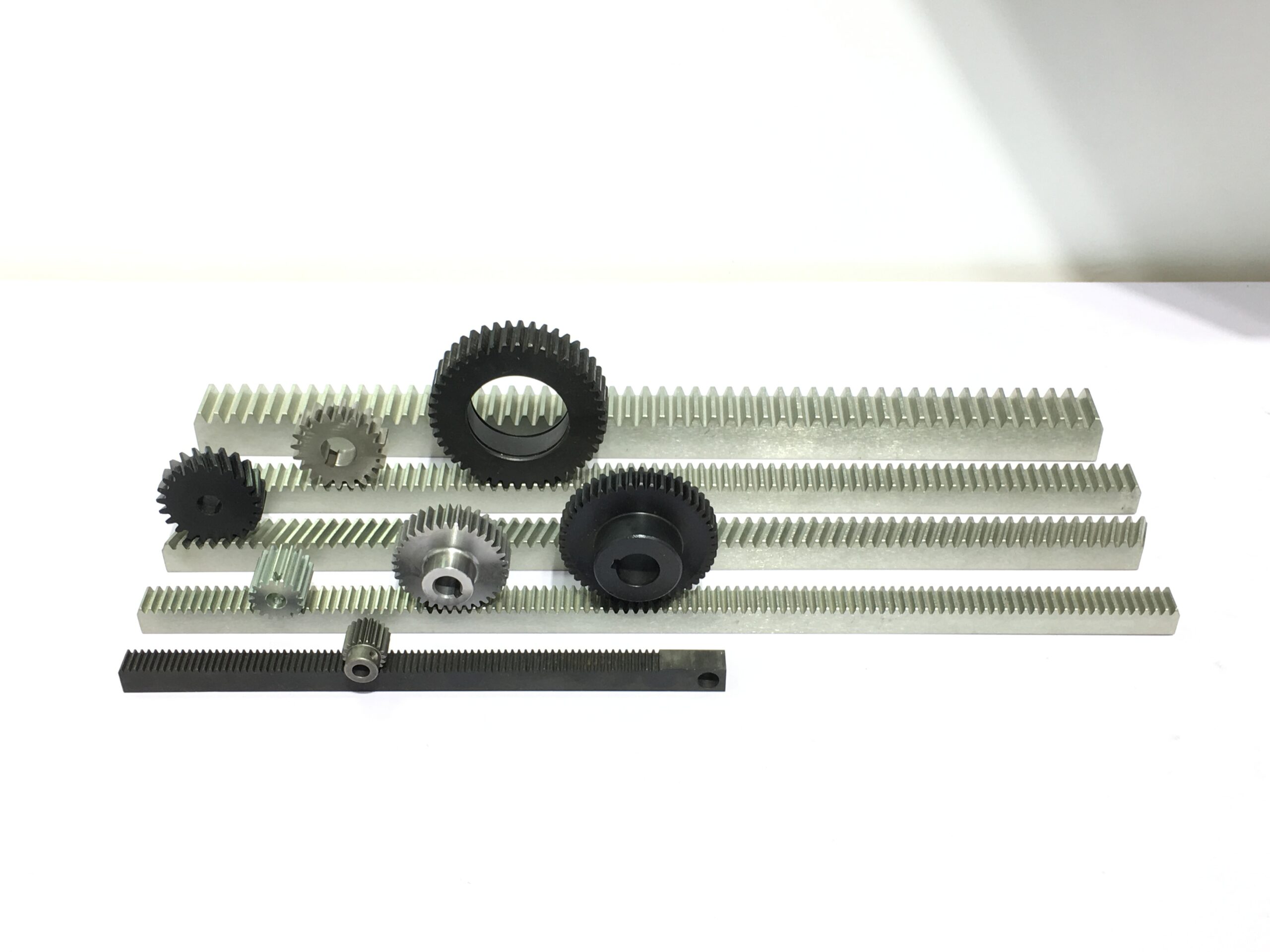

Gear Rack M1.5/M2/M3/M4/M5/M6/M8 CNC White Galvanized Rack

- Material: SAE1020, SAE1045, Cr12, 40Cr, Y15Pb, 1214L, 20CrMnTi, 16MnCr5, 20CrMnMo, 41CrMo, 17CrNiMo5etc

- Surface Treatment: Black Oxide/Zinc Plated/Nickel Plating/Electrophoresis

- Teeth Number: 9 - 300 Teeth

- Module No.: M1 M1.5 M2 M2.5 M3 M4 M5 M6 M7 M8

- Length: 500-5000mm, could be customized

- Gear Processing: Gear Hobbing, Gear Milling, Gear Shaping, Gear Broaching, Gear Shaving, Gear Grinding and Gear Lapping

Gear Rack Descriptions

| Gear Rack Material | Steel C45, Stainless Steel, 20CrMnTi, 16MnCr5, 20CrMnMo, 41CrMo |

| Surface Treatment | Electrophoresis, Zinc Plated, Black Oxide, Phosphate, Nickel Plating, Chrome Plating, Chemical Nickel Plating, Hard Anodizing, |

| Heat Treatment | Quenching, Tempering, Carbonitriding, Carburization, Annealing, Normalizing |

| Teeth Number | 9 – 300 teeth |

| Length | 500 – 5000mm, could be customized |

| Module No. | M1 M1.5 M2 M2.5 M3 M4 M5 M6 M7 M8 |

| Production Capacity | 25000 PCS/Month |

Our steel Gear Racks are exported in big quantity to Europe,America etc.Our gear racks producedby,CNC machines.Our steel gear racks,cnc gear racks,gear racks M1,racks and pinion steering gears are exported in big quantity to Europe,America,Australia,Brazil,etc.There are standard gear racks available and also special gear racks as per your drawings or sampls.Standards or special gear racks produced by CNC machines.

1. Material: Carbon steel, stainless steel, aluminium alloy, plastic, brass etc.

2. Module: M1, M1.5, M2, M3, M4, M5, M6, M7, M8 etc.

3. The pressure angle: 20°.

4. Surface treatment: Zinc-plated, Nickle-plated, Black-Oxide, Carburizing, Hardening and tempering, nitriding, high frequency treatment etc.

5. Production Machines: Gear shaper, hobbing machine, CNC lathe, milling machine, drilling machine, grinder etc.

6. Heat treatment carburizing and quenching.

7. Surface disposal: forced shot-peening.

Applications of Gear rack

Gear Rack is used in many industry such as: the mining, metallurgical, cement, chemicals, construction, buiding materials,

electric power, telecommunictions, textiles, and also the transportation departments.

Such as:

- conveyor:Belt conveyor,AFC conveyor, chain conveyor, and also screw conveyor.

- Pum:Water pump, oil pump, and also slush pump, etc.

- Fan: Draft fan, fanner, boil fan, and also etc.

- Excator:bucket excavator bucket, and also wheel excavators .

- Crane:Tower crane, gantry crande and also bridge crane.

- Others:Various elevators, coal plough, ball mill, crusher, and also recreation machine.

- Blender equipment, centrifuger, washer, leather-making machine, machine for recreation park mixer wire drawing machine.Extruder, dregs crusher of boiler.

- Plastic feeder, rubber smelling machine, etc.

Advantages of Lied

- More competitive prices,

- Shorter delivery date: 35 days.

- We are the professional manufacturer in the field of Power Transmission Parts, specially for gear rack.

- Produce standard and also customized

- Strict QC Management:ISO9001:2008,our engineer,Mr.Wang has specialized in the prodcution for over 20 years now.

Packaging & Shipping of Gear Rack

We using caton box for individual package for each gear rack,or,you can also choose the pallet packing.

MADE IN CHINA can be pressed on wooden cases now.Land,air,sea transportation are available.

We support carrier such as UPS,DHL,TNT,FedEx and EMS.